Helpful Hints – Recycled vs Virgin Rubber

Rubber can be broadly divided into two distinct categories: recycled rubber and virgin sheet rubber. While they both share the similarity of being rubber materials, each has its own unique characteristics that makes it useful for very specific situations. Before you dive into our product line, take a moment to learn about the differences between recycled rubber and virgin sheet rubber.

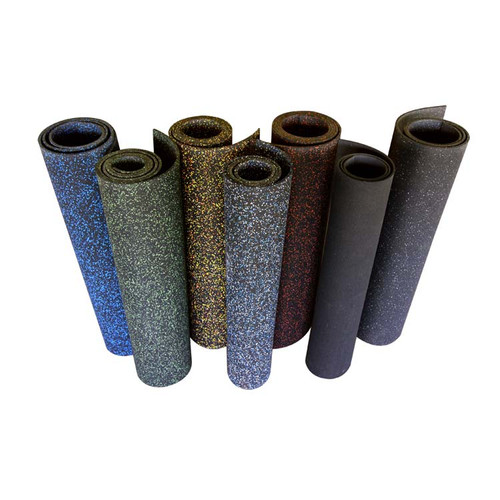

Recycled Rubber: This type of rubber is made from post-consumer rubber products, primarily from discarded vehicle tires. These tires are shredded into very fine crumb material, almost like a powder, and then glued back together with a polyurethane-based binder. The end result is a solid rubber sheet that has a somewhat grainy texture to it. Since recycled rubber is composed of tires that would otherwise waste away in landfills, it is considered an eco-friendly product because it is repurposing that non-biodegradable material into something new and useful. This helps make recycled rubber a more cost-effective option compared to many of its virgin rubber counterparts. You should use recycled rubber for applications that require physical durability and UV resistance. It is a very popular flooring option in areas such as gyms and offices. It is also popular for situations that require rubber products that have to be left outdoors, exposed to all manner of environmental variables such as intense sunlight or rainfall. One drawback is that recycled rubber does not fare too well against compounds such as mineral spirits or oils and greases. Overall, recycled rubber is highly recommended for general-purpose applications when you are on a tight budget.

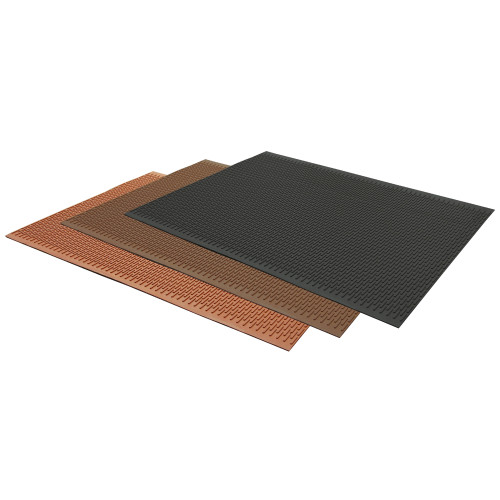

Virgin Sheet Rubber: While recycled rubber is more general-purpose in nature, virgin rubber materials are highly specialized products that are intended for specific applications. The term “virgin rubber” in this context is rather broad because it encompasses different compounds of rubber ranging from natural rubber to synthetic rubbers like neoprene and silicone. Unlike their recycled rubber counterparts, virgin rubber sheets have a more finished appearance. They also bring a lot more variety in terms of color, with options available in red, white, and blue, just to name a few. You should use virgin rubber products in cases where you have a very specialized type of application. For example, industrial-grade applications involving the presence of oils and greases call for a rubber such as nitrile or neoprene. Another example is for an application involving very extreme temperatures, and in those cases, silicone rubber is the best option to pursue. Virgin rubber materials are often synthetic in nature and thus are not considered eco-friendly. As a result, they are a bit higher in price compared to eco-friendly recycled rubber. They are, however, well worth the price because these virgin rubber materials are designed to perform for highly specialized purposes.

Rubber Flooring Insights - Tiles vs. Rolls

Rubber flooring is an outstanding option for use in a wide range of settings and applications. But it usually comes in two different forms – rubber rolls and modular tiles – with each form suited to different settings and needs. So, when should you opt for modular tiles rather than flooring rolls?

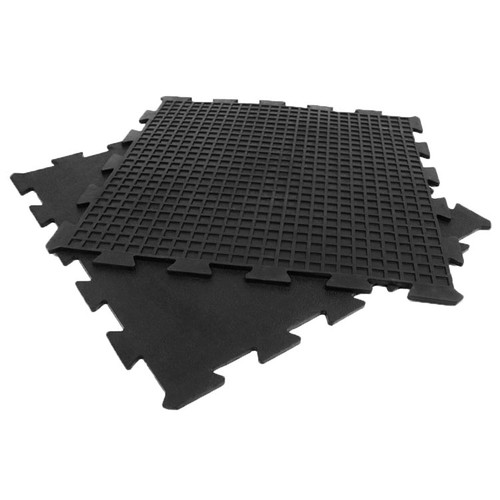

As you might expect, rubber flooring rolls and tiles are very similar in many respects and share several key characteristics. Both are designed to provide high-performance surfaces which are comfortable, high-grip, durable, and protective. But modular tiles also have a series of qualities which are specific to them. Perhaps the most obvious is that they are smaller, lighter, and easier to handle than full rolls. They are interlocking products, coming in small sections that fit together using pins or puzzle edges to create a larger area. This means that tiles are easier to handle, store, and transport, but also makes them supremely easy to install. The main situation in which tiles should be used rather than rolls is when a priority is simple installation. One person can lay a rubber tile floor without the need for help or messy adhesives.

Another situation in which tiles present the better choice is in a room where specific areas might see heavier wear than others. Individual tiles which have suffered significant wear or damage can be swapped out for new tiles, without the need to replace the entire floor. A great example of this is in a gym, where pressure points around heavy machines and weights will wear faster. Modular floors are also more versatile and can easily be pulled up and moved to a different room or area. You can also expand an area simply by adding more tiles. You can even mix and match different colors to create unique aesthetics with a tile floor. Modular tiles offer the best choice when you specifically need versatility and easy installation.

-

-

-

-

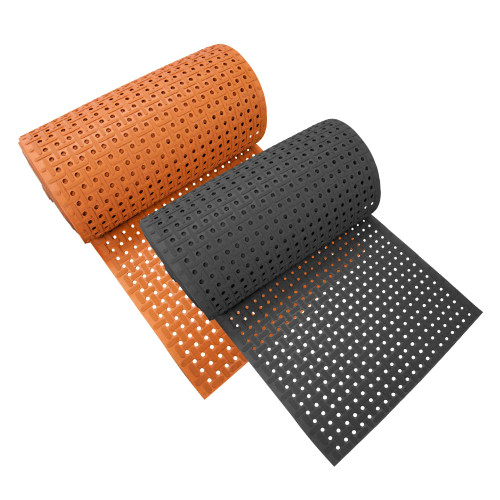

"Terra-Flex Sport" Rolls

$275.00 - $595.00

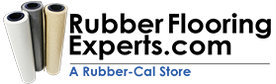

Rubber Flooring for Industrial Zones

Industrial locations, such as warehouses and construction sites, are subject to many conditions that most places do not have to deal with. These conditions include heavy machines and hazardous materials, among other things.

While rubber flooring is useful in most settings, its value shines in industrial settings. For one thing, workers in places like warehouses are on their feet for most of their shifts. This can lead to bodily pains and aches that affect productivity in the long run. With rubber flooring such as comfort matting or corrugated runners, though, employees will return from work less fatigued, ready for the next day. Furthermore, heavy machinery, over time, tends to damage subflooring (even concrete!). Thus, to avoid the expensive repair fees that can potentially plague your industrial site, install rubber flooring as a preventative measure.

Moreover, because rubber is naturally water- and slip-resistant, a rubber surface prevents water from leaking into your subfloors and reduces the likelihood that a worker will accidentally slip and fall. These are just other ways in which rubber floors ultimately save you money—an investment that pays for itself over time.

-

-

-

-

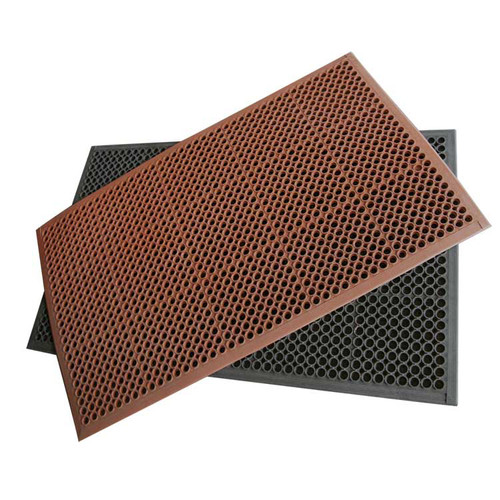

"Fishbone-Pattern" Rubber Flooring

$15.00 - $300.00

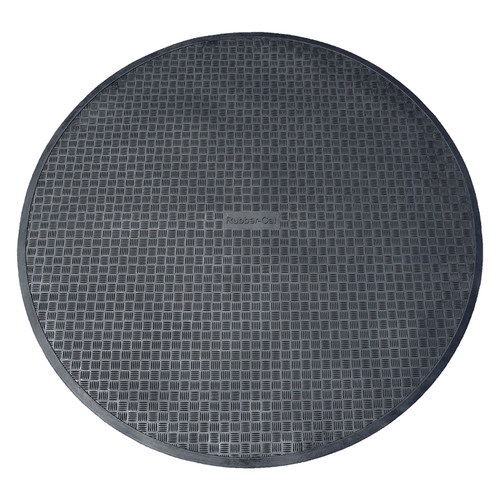

A Rubber Gas Station Mat Protects Fuel Sumps from Flooding

Fuel sumps are essential to gas stations. Gas stations refuel countless numbers of cars every day, and they rely on underground storage tanks to store their fuel. Fuel sumps are the access points through which convenience stores have their fuel tanks replenished.

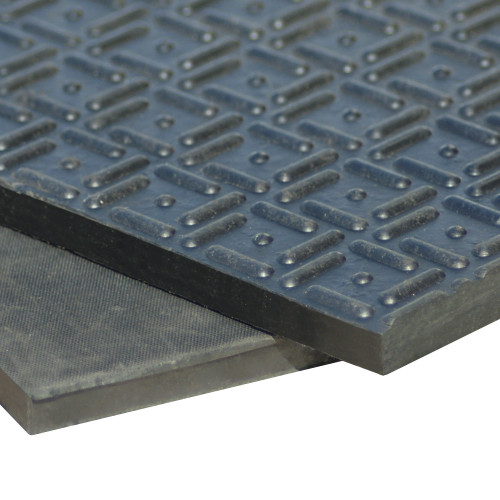

While this seems simple enough, fuel sumps face a range of complications. Foremost, rain often seeps into fuel sumps, flooding them and requiring gas-station workers to pump out the overflow. A gas station mat—when placed over a fuel sump’s manhole—keeps rainwater and other contaminants at bay when the fuel sump is at risk of flooding.

A gas station mat should be large enough to cover the fuel sump, and it should be made of rubber, since rubber is water-, chemical-, and abrasion-resistant. Thus, a rubber gas station mat can withstand the crushing weight of heavy vehicles, as well as resist water when it tries to seep into fuel sumps.

-

Diamond-Grip Gas Station Mat

$135.00 -

Gas Station Mat

$115.00 -

-

"Fishbone-Pattern" Rubber Flooring

$15.00 - $300.00